Drop Test Machines: Simulating Real-World Impact Scenarios

The product’s quality, durability, and safety assurance are essential in technology and fast-paced innovations. Manufacturers put strict efforts into machines, automobiles, or electric gadgets to get the best results in real-world experience. These machines must be tested before being displayed in marketplaces to ensure the quality and durability of products. A drop test machine, called a drop tester or drop test equipment, is one of these assortments. This article will focus on drop-test machines’ significance, functionality, and applications. We will also emphasize the critical role of drop test machines in checking the reliability of products.

Drop Test Machine Brief Understanding:

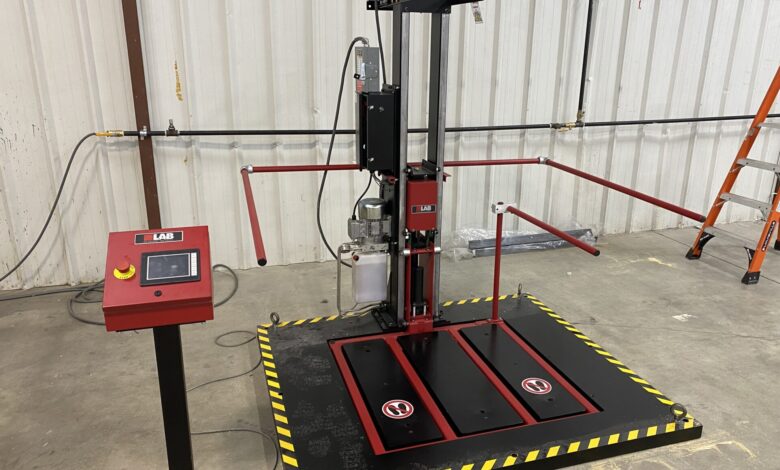

These machines are instruments designed to test controlled impacts. These include handling, shipping, or accidental drops. These machines activate in situations when objects are being moved or fall accidentally. These machines range from simple to complicated. With solid frames, it has different parts for testing. The sensors of drop testing machines detect the object’s fall and measure its impact forces.

Functions:

A drop testing machine’s central principle is knowing the impacts on the object in uncertain situations. Companies use this machine to check the strength of products when they accidentally face a fall from different angles and heights. These controlled situations help manufacturers know their products’ reliability and durability. They analyze the quality of product materials that may compromise performance or safety.

Features:

Sensors for Drop Impact: sensors in the test machine measure the force applied to a product and how that force affects the material used in the product. Sensors provide the analyzed data on product durability.

Drop surface: this drop platform provides the surface and height from which the object falls and hits the surface. It provides analyzed data on hits from different angles and heights.

Control Slab: The control panel allows people who test to customize the drop height, the number of times the product is dropped, and customized conditions for testing.

Features for safety measures: Drop testing machines provide safety measures. It can avoid accidents and not harm the product. It has interlocks and safety guards for the protection of the product.

Applications:

Drop test machines are used across different industries and manufacturing fields. They can test the controlled impacts of products. The electronic industry is one of the leading industries that need drop test machines to analyze product damage resistance. Other than the electronic industry, there is the automotive sector. In the automotive sector, drop test machines are set to test the durability of automobile parts. Such as bumpers, dashboards, and engines. In the packaging industry, drop test machines are necessary before dispatching items to ensure safe delivery.

Benefits:

Rigorius drop tests provide quality assurance of the product. It analyzes the item’s potential and weaknesses, which results in improved quality and durability. Drop test machine usage saves companies from huge losses. Because it identifies the deficiencies of products before investing considerable amounts in the large production of items. It also helps industries to evaluate how much warranty could be provided for an item. Industries have standards of quality and regulations. They are secured by pre-testing items by drop test machines to maintain compliance and liability of the company. Drop test machines also benefit companies in keeping their commitment to safe products and durability. It will enhance their reputation.

Advancement in drop test machines:

Drop test machines have evolved through the years to meet the needs and demands of industries. New machines provide different features for innovative products of growing technologies. Advanced drop test machines have advanced components. Such is a new parameter for controlled conditions, data acquisition systems, and software interfaces. They can guess the detailed analysis and give exact customization as required. Other than that, advanced features like pneumatic actuators, servo motors, and high-speed cameras have benefitted industries in analyzing the accuracy and efficiency of drop testing procedures.

Conclusion:

Drop testing machines play a vital role in the pre-testing of products before setting them up in the markets. It tests the products with different controlled situations. Such as heights, angles, and equipment. These other tests analyze the impacts on the product in uncertain situations. These tests identify the weaknesses and strengths of products, which helps industries. They can improve the alteration of products. Companies invest money in innovative drop testing machines. This gives them quality control measures and results in customer satisfaction. The technology and features of drop testing machines are also advanced. It enables industries to maintain high product quality standards, with growing complexities and competition in the marketplace where consumers’ demands and expectations increase. The expectations of reliability are challenged and analyzed by drop-testing machines. It meets the commitment to excellence of industries.